Your air-to-water heat pump stops heating for a moment and you see steam coming from the outdoor unit… Don’t worry — this is not a malfunction, but a normal defrosting cycle. In this article, we explain why this process is essential for reliable winter operation and how modern Master Therm control systems manage it efficiently.

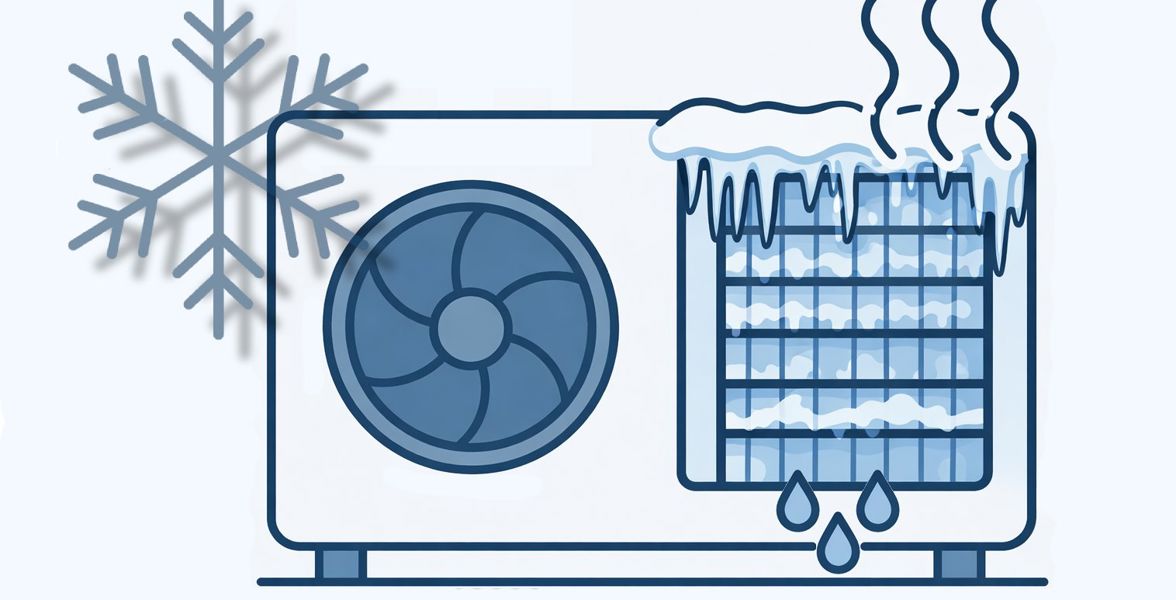

In air-to-water heat pumps, the outdoor unit is equipped with an evaporator through which ambient air flows. When temperatures are low and humidity is high, frost begins to form on its surface. This reduces the airflow and decreases the evaporator’s ability to extract heat from the surrounding air.

To maintain efficiency and reliable operation, the heat pump’s control system must continuously monitor the operating conditions of the refrigeration circuit. A key parameter is the temperature difference between the outdoor air and the refrigerant inside the evaporator. If the system detects that heat transfer has dropped outside the allowed range, the defrost cycle is activated.

At what temperatures does the evaporator freeze the most?

The heaviest frost formation does not occur during severe cold spells, but at temperatures between –5 °C and +3 °C. In this range, the air is cold and very humid, so moisture easily condenses on the cold evaporator and quickly forms ice. In contrast, at temperatures below –10 °C the air is much drier, frost builds up more slowly, and defrost cycles are less frequent. This is why air-to-water heat pumps typically defrost more often around freezing temperatures than during periods of deep frost.

When is the defrost cycle activated?

The heat pump can activate the defrost cycle only when all of the following conditions are met:

the temperature difference between the air and the refrigerant is outside the allowed tolerance (indicating reduced heat transfer),

the outdoor temperature is below 12 °C,

at least 45 minutes have passed since the previous defrost cycle.

If the control system evaluates these conditions as fulfilled, it begins to prepare the unit for the defrost cycle.

How does the defrost cycle work?

Once the defrost mode is activated, the heat pump:

stops the outdoor unit’s fan,

briefly reverses the refrigeration cycle using a reversing valve (usually for 3–5 minutes),

directs heat from the indoor heating system into the evaporator to quickly and effectively melt the accumulated ice.

This process is short, controlled, and energy-optimized. When the defrost cycle is finished, the heat pump immediately returns to normal heating operation.

During defrosting, a large amount of condensate often drips from the evaporator, and toward the end of the cycle dense white steam may appear — this is completely normal.

How can you recognize defrosting on the display?

The pGDx touch panel displays the defrost cycle using a snowflake symbol with droplets, shown in two different states:

Symbol flashing – Defrost preparation

The heat pump has met all conditions for the defrost cycle and is waiting for the physical start of the process.Symbol steady – Active defrosting

The defrost mode is now active and the heat pump is supplying heat to the evaporator. It is normal for a significant amount of condensate to form during this phase, as well as visible steam toward the end of the cycle.

Why is proper defrosting so important?

Without regular and controlled defrosting, the evaporator would gradually freeze over, leading to:

a dramatic drop in efficiency,

increased electrical consumption,

potential damage to the outdoor unit,

unstable operation of the heat pump.

Modern Master Therm control systems optimize the defrost process so that it is activated only when truly necessary — ensuring both high efficiency and long-term reliability of the entire system.