Master Therm heat pumps are used to cool a particle accelerator at a research institute near Prague.

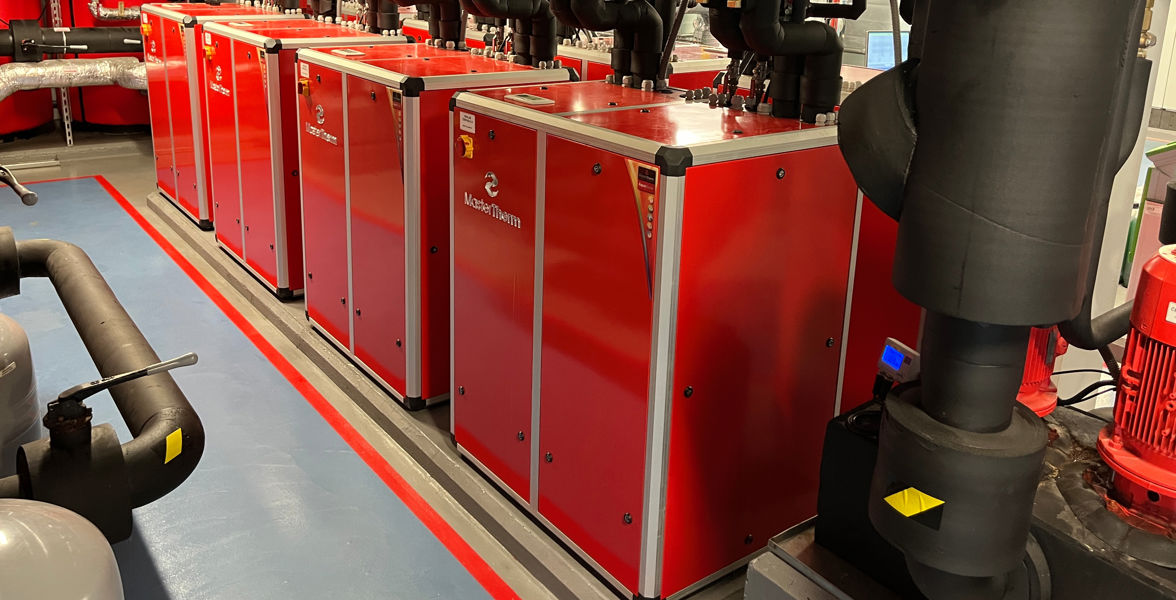

Two cascades, each comprising four water-to-water heat pumps, were installed at the Institute of Nuclear Physics of the Czech Academy of Sciences in Řež.

Efficient heat recovery

The first cascade provides cooling for the cyclotron particle accelerator located in the basement of the building. The heat pumps operate in a heat recovery mode, using waste heat for space heating and domestic hot water production. During summer operation, when the accelerator generates excess heat, this surplus is dissipated via dry coolers installed on the roof.

- Total cooling capacity: 690 kW

- Total heating capacity: 860 kW

Dry coolers that can also heat

The dry coolers also support a reverse operating mode, where they absorb heat from ambient air. In winter, they enable the system to work in an air-to-water mode, especially when the accelerator is not in use. The heat is extracted from the air through glycol loops and transferred to the heat pump cascade, again serving for building heating and hot water supply.

A unique feature of this installation is the defrosting system for the dry coolers. When there's a risk of icing during heat absorption from cold air, so-called subcoolers are used for defrosting. These subcoolers recover residual heat left over from the main heat exchange process—effectively using energy that would otherwise go to waste. This makes the defrosting process nearly energy-free.

Heat pumps instead of traditional cooling

The second cascade is dedicated primarily to summer cooling of interior spaces, including precise temperature control in radiochemical laboratories.

A multifunctional and flexible system

The installed solution is highly versatile and supports various modes of experimental operation. The system combines heat recovery, air-to-water heating, active cooling, and even passive cooling via dry coolers.